| Listing ID: | 145 |

| Services type: | 3D Materials |

| Address: | Granutools SRL Rue Jean Lambert Defrene 4340Awans Belgium |

| Price: | Price on asking |

| Description: | GRANUTOOLS : our company We are building up on a unique powder knowledge by making the bridge between industrial processes and powder properties.

We are a customer-centric company, our goal is to support our customers' efforts in R&D and production handling powders.

Granutools has been created to fill in a gap left in the market for decades between manual powder testers and time-consuming experiments.

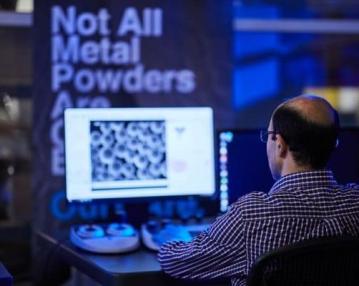

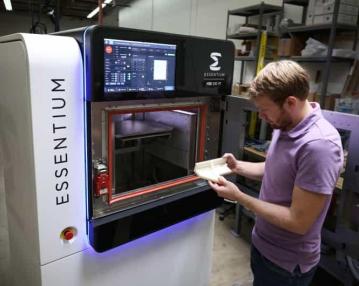

Additive manufacturing: Granutools is also a supplier of powder characterization instruments for the additive manufacturing industry. Working with top tiers R&D centers, we have developed unique know-how available to our customers. Granutools unique powder characterization Workflow for AM powders offers best-in-class process optimization. And this means better parts, faster ramp-up, and smarter powder lifecycle management Pharmaceutical: Powders are widely used in pharmaceutical applications as an excipient or active ingredient in formulations. Consequently, many production processes are dealing with powders: tableting, wet and dry granulation, blending, caps filling, etc. Therefore, any progress in the understanding of powders flowing behavior can have huge consequences for pharmaceutical industries. Indeed, a powder with inappropriate flowing properties can cause serious complications in production lines (clogging, agglomeration, segregation, etc.). Most pharmaceutical customers refer to Pharmacopeia when it comes to quality control of their production process. To this end, we offer compliant tap density (Granupack) which can comply with almost any standardized tap density test thanks to its unique software. The angle of repose meets stringent initialization protocol with the Granuheap. The fully automated tester has best in class precision and repeatability results and almost no operator dependency. Ceramics: Food: Granutools is also a supplier of powder characterization instruments for the food industry. Working with a wide ranger of top actors producing anything from flour to spices. Granutools unique powder characterization range of equipment allows high versatility regarding the range of compatible powders. No matter what your product is, contact Granutools to get more data on your application. Metals: Minerals: Chemicals: Granular materials and fine powders are widely used in industrial applications. To control and to optimize processing methods, these materials have to be precisely characterized. The characterization methods are related either to the properties of the grains (granulometry, morphology, chemical composition, …) and to the behavior of the bulk powder (flowability, density, blend stability, electrostatic properties, …). The chemistry of the particle or the coating can change the behavior of a powder. In that sense, Granutools made several studies on chemicals to understand the impact of such change on powder flowability. Academics: Due to their innovative nature, Granutools’ instruments appear in many publications (more than 30 in 2019!) and are used by state-of-the-art research institutes. Also, their modularity, size, and easy access to raw data allow academics to quickly tune them to their special needs as shown in the examples below.

|

| PRODUCTS AND SERVICES: | Metals Powders Ceramics Material analysis Miscellaneous systems and machines Miscellaneous metrology |

| Type: | Sell |

Chinese

Chinese Deutsch

Deutsch Русский

Русский Español

Español

There are no comments yet

Leave a Comment